CERN Neutrino Factory

Working Group Technical Note

R. Horne, C.D. Johnson

25/11/99

(from previously unpublished material)

Post-irradiation Examination

of a High-Intensity Proton Beam Target

This Technical Note was

distributed at CERN in manuscript form on 10/10/85. It contained several

colour photographs.

There has recently been a renewed

interest in high-intensity and high-power proton targetry for neutrino

production and nuclear spallation sources. We have taken advantage of the

newly available techniques of Web publishing and computer enhancement

of photo images to re-issue the original document in an updated form.

At the time of this study the CERN Proton

Synchrotron, PS, could deliver a beam onto the antiproton target of up

to 5 bunches, spaced by 105 ns, per machine cycle (pulse) with the following

properties:

| Energy |

26 GeV |

| Intensity (maximum) |

2.5 x1012 p/bunch |

| Repetition rate (max.) |

0.4 Hz |

| Bunch length (4sigmaz) |

25 ns |

| Beam spot size at target of (4sigmar)

|

1.6 mm |

| Energy deposited in target (50 mm) |

1.5 kJ per pulse (5 bunches) |

| Peak energy density in beam: |

50 kJ mm-2 per

pulse |

| Mean power absorbed in target at maximum repetition rate |

600 W |

The antiprotons (and other secondary particles - notably

negative pions) produced in the target were collected (focused) by a lithium

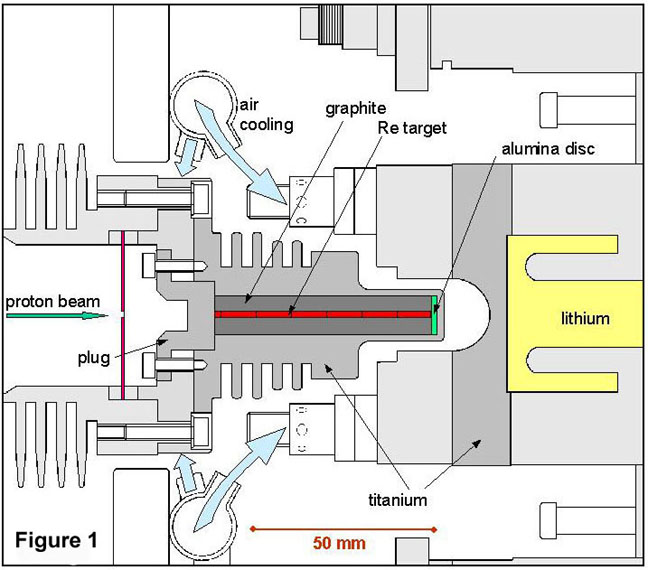

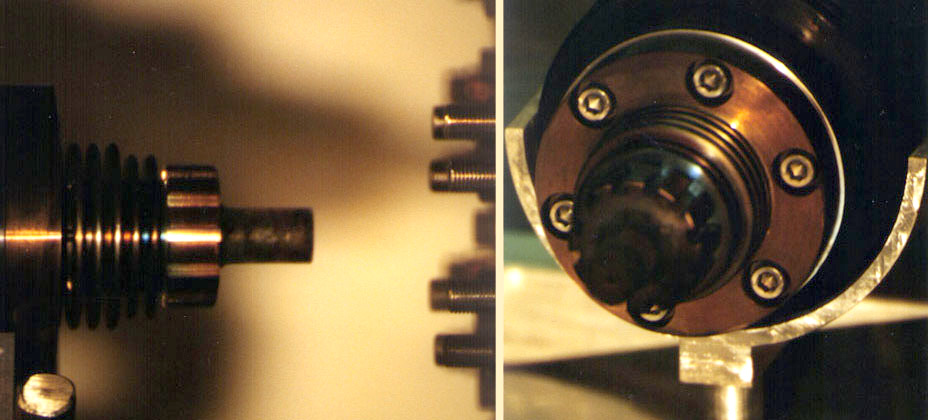

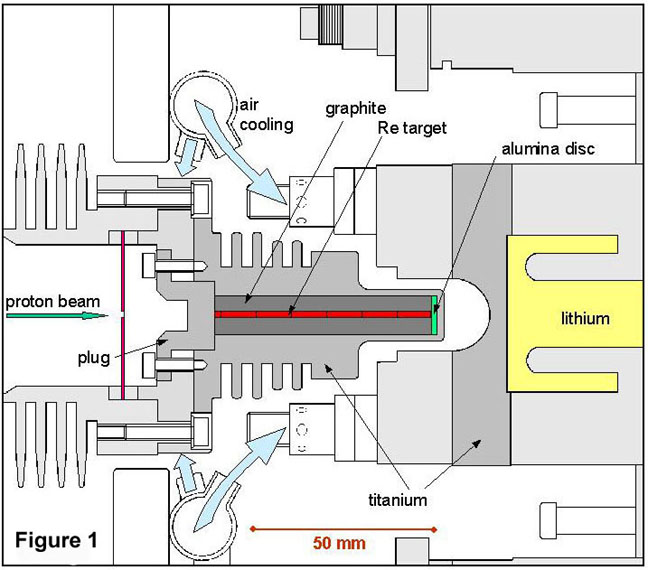

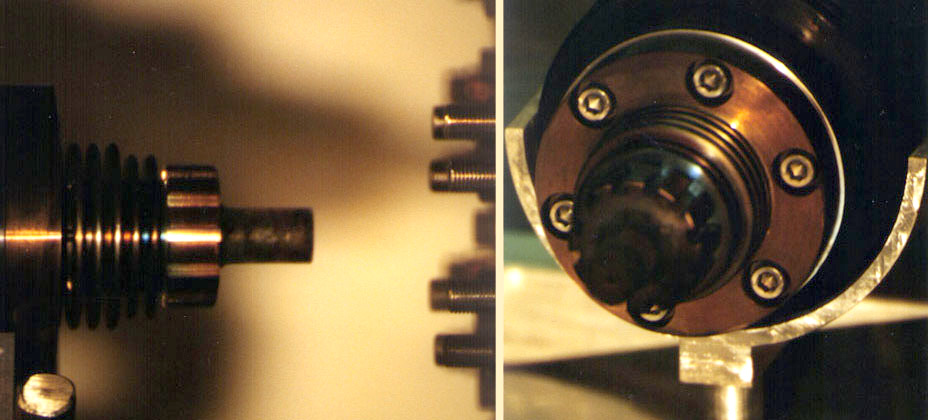

lens placed very close to the target as illustrated in Figure 1: Target + Li Lens. The

high-density target was a 3 mm diameter x 50 mm length rod of rhenium (later

iridium was used) pressed into a graphite cylinder, itself a press fit

inside a finned titanium container that was bolted on to a finned aluminium

heat sink with a black anodised finish (seen to the left of the target

assembly in Figure 1). The whole assembly - target plus heat sink

was air cooled. Some photographs of the target and target/lens assembly

installed in the antiproton production zone are shown below.

Click on the photos to see enlarged images

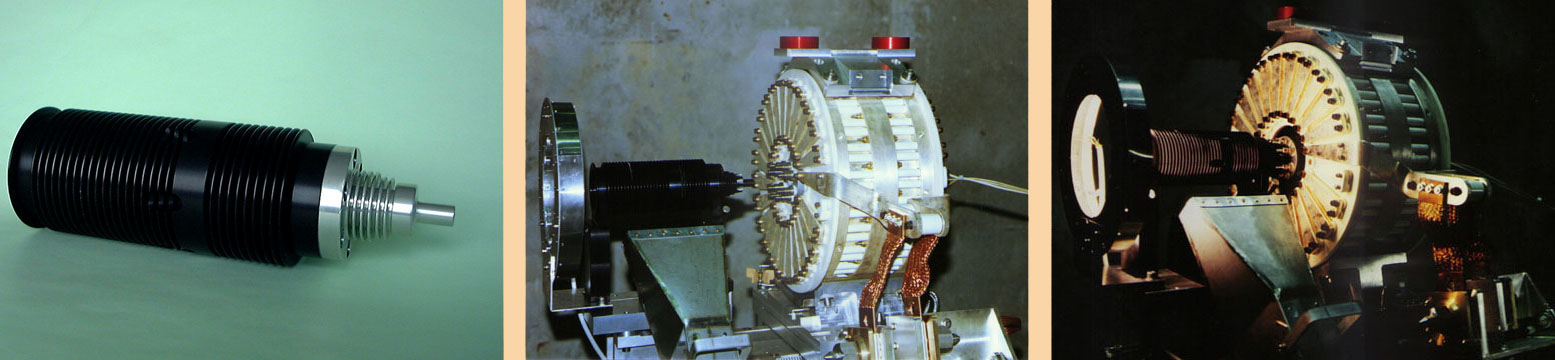

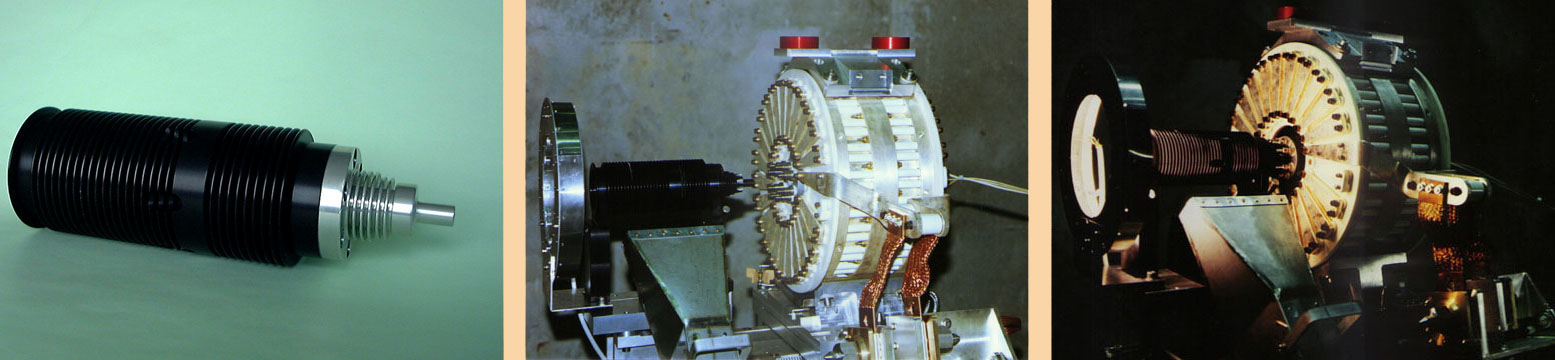

a) A target assembly, b) a similar target mounted

upstream of the lithium lens, c) the target/lens installed in the beamline

with illumination for TV monitoring

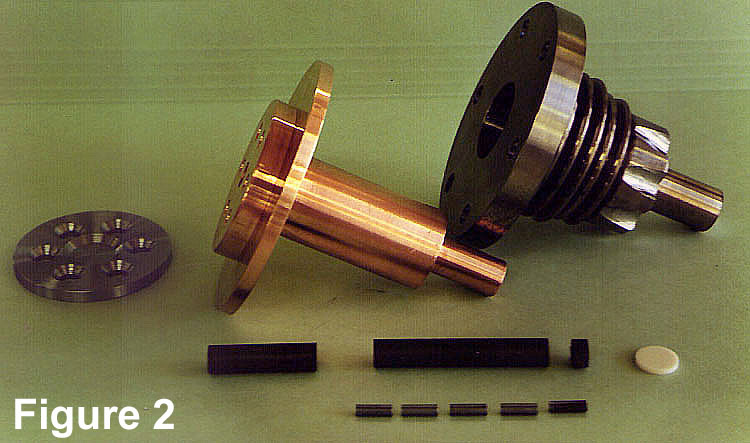

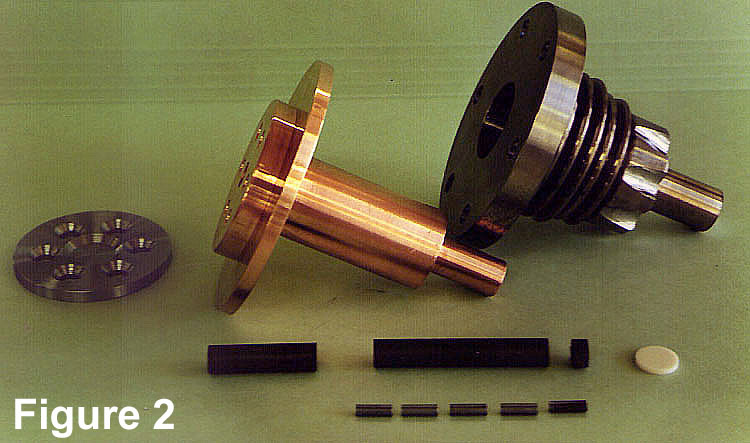

The component pieces of a typical target before assembly

are shown in Figure

2. In this version a copper heat sink was installed between the graphite

and the titanium container. The rhenium core was made up from pieces 3

mm diameter and 10 mm long. The alumina disk at the downstream end of the

rhenium core was introduced to improve the fatigue lifetime of the downstream

exit window of the titanium container. Previously two steel containers

had ruptured on axis at the exit window after 105

beam pulses. This was attributed to fatigue failure.

The target chosen for post-irradiation dissection had

the simpler form shown in Figure 1.

By removing the upstream plug and then cutting through the target snout

immediately in front of the alumina disc, the target and its surrounding

graphite cylinder could be pressed out from the titanium container The

graphite cylinder was then sheared longitudinally with a special tool exposing

the rhenium rods for visual inspection. The target had been irradiated

for six days and, taking account of beam intensity fluctuations and duty

cycle, the estimated total proton flux was between 1 and 1.5 1017

protons. Previous experience with tungsten and rhenium targets had led

us to expect that the rods would be shattered by beam-induced thermal shock

soon after the start of irradiation at full intensity. Our target was designed

to contain the fragments within the graphite sheath. The time evolution

of normalised yield of secondary particles (antiprotons, electrons, negative

pions) measured seperately after startup, indicated that breakup reduced

the effective target density by less than 10%. Earlier results from long-term

irradiation of copper targets in graphite had indicated a more important

loss of up to 30% in effective density due to fracture and void formation.

Our purpose in carrying out this post-irradiation target

inspection was to study the fracture pattern and to confirm our calculation

that most of the damage would occur in the downstream end of the rhenium

rod where the heat load was greatest, see Figure

3.

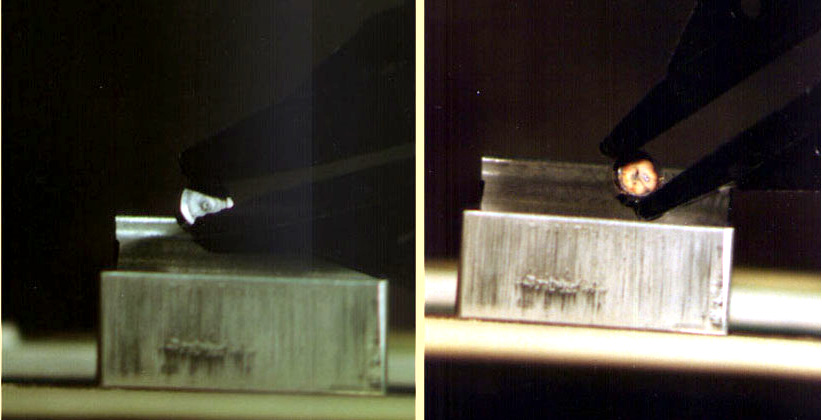

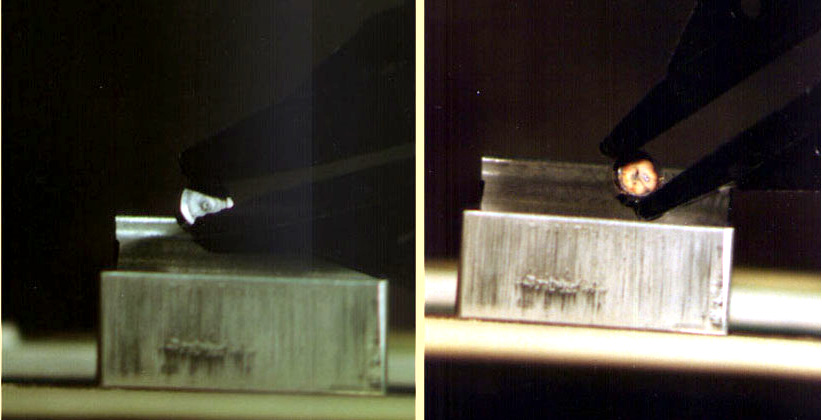

In the following set of four pictures, Photos 1 and 2

show the target before dissection. The target snout was subsequently sliced

through at the interface between the graphite and the alumina disc and

a further slice of 10 mm length was cut off the end of the snout. Photo 3

is a view of this slice from the downstream end exposing the rhenium core,

the graphite plug and the outer sleeve of titanium. Photo 4 shows

the upstream face of the alumina disc - it exhibits radial cracks. Click

for an enlarged view.

|

Photo 1 Photo2

|

Photo 3 Photo4

|

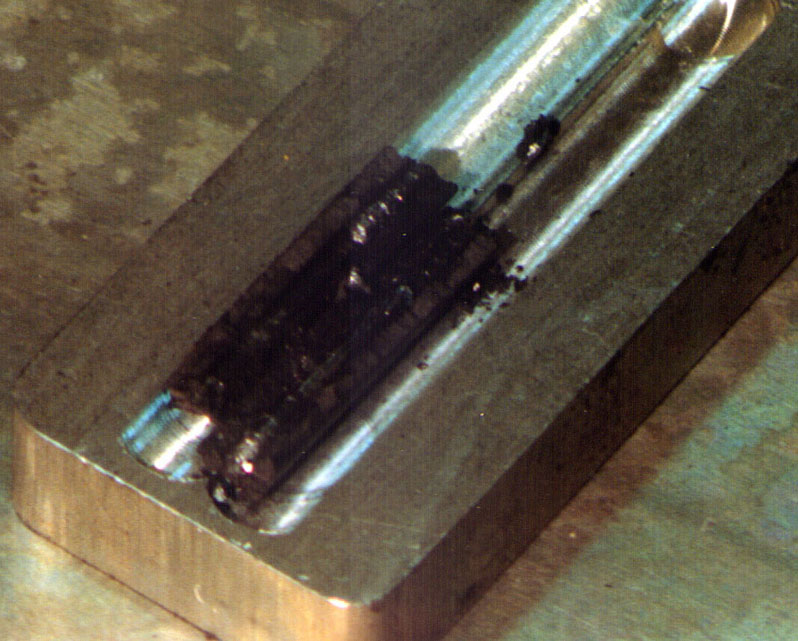

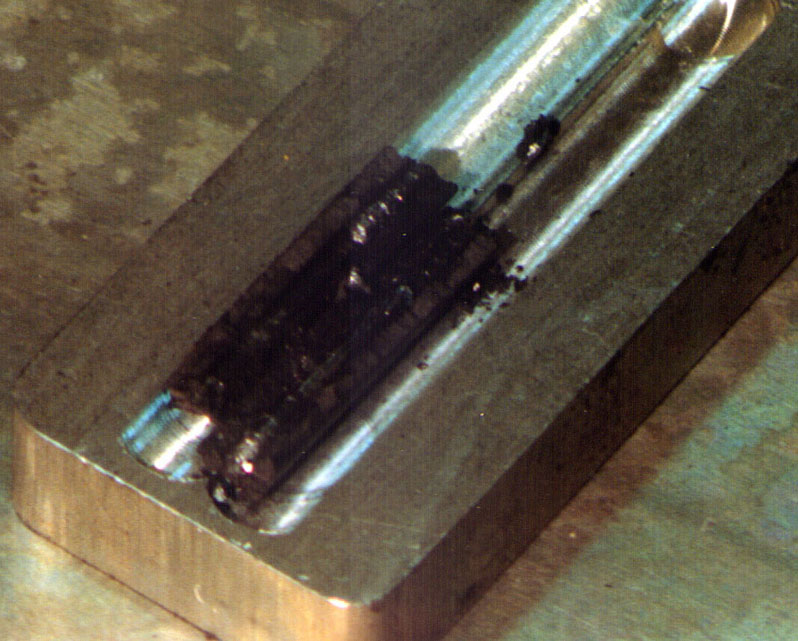

The graphite slug containing the

10 mm downstream end of the target was then pushed out from the titanium

sleeve and split. The rhenium was in fragments and these are shown in Photo

5.

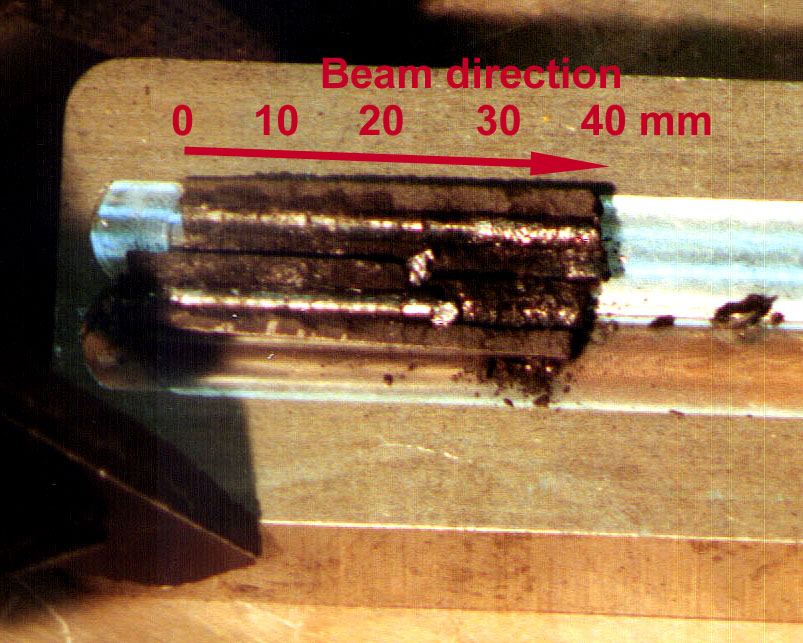

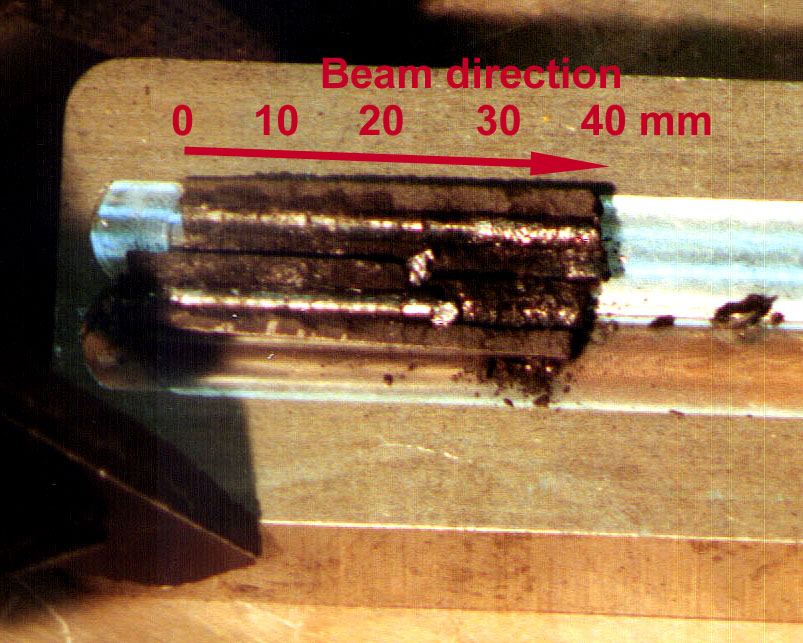

The remaining upstream 40 mm length

of rhenium was still inside the main body of the target (Photo 6). It was

pressed out and the surrounding graphite cylinder was split over its entire

length. The results are shown in Photos 7 and 8. The greatly enlarged views

(click on the photo) show that the rhenium in the upstream 30 mm has

broken into many short lengths and that the region from 30 mm to 40 mm

had disintegrated in a similar way to the 10 mm end section (Photo

5). This qualitatively confirms the prediction (Figure

3) that the maximum thermal shock is expected in the downstream 40%

of the target.

|

Photo 5

|

Photo 6

|

|

Photo 7

|

Photo 8

|

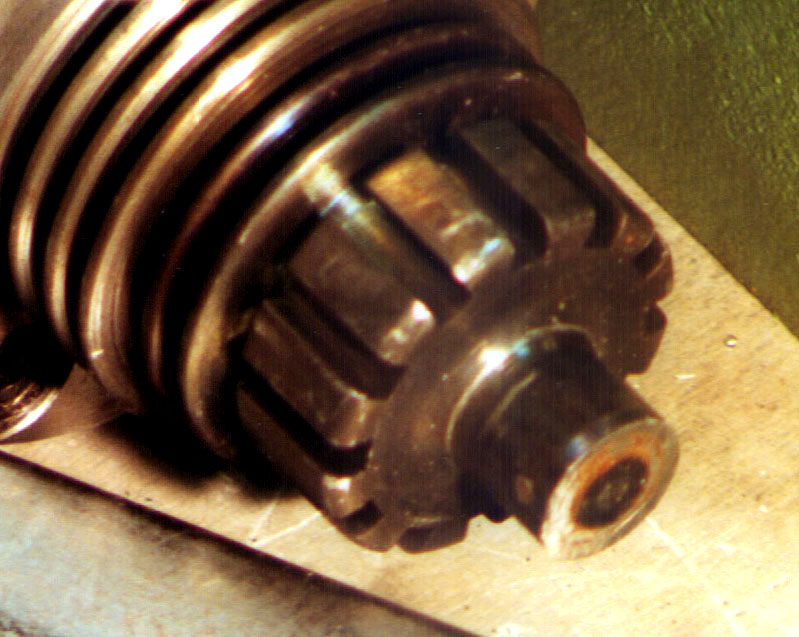

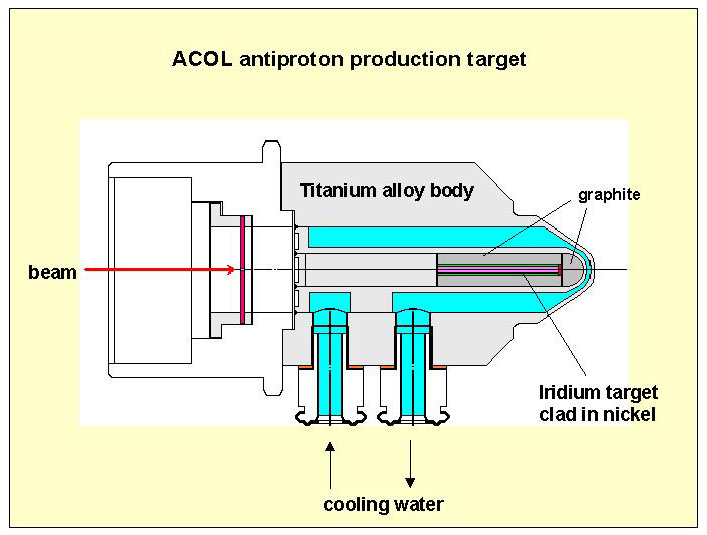

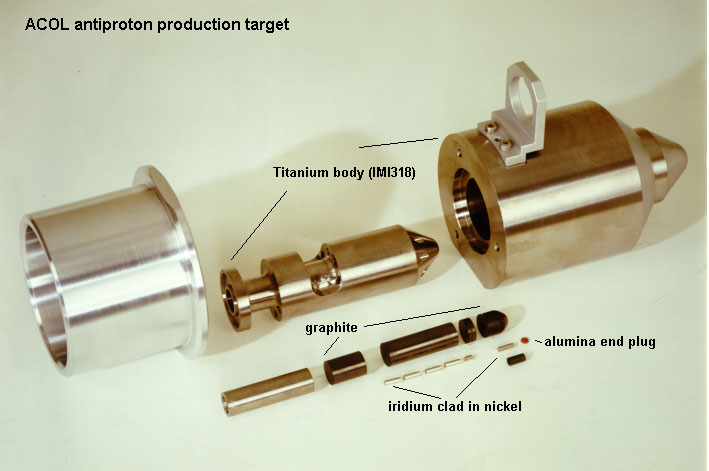

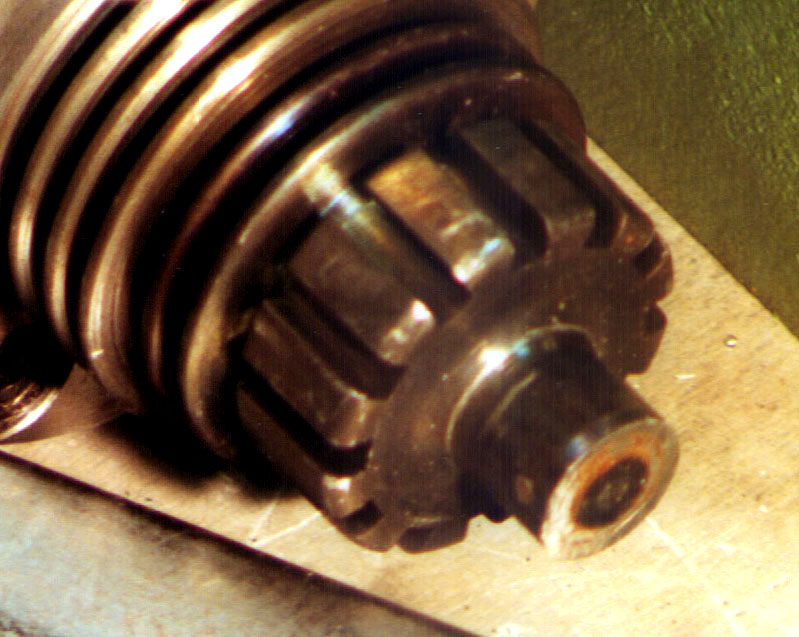

Summary These

photographs confirmed our understanding that within the antiproton targets

the high-density target material (rhenium or iridium) was shattered by

beam-induced thermal shock, but that the fragments could be contained to

provide a target with an effective density better than 90% of the solid

material. A subsequent improvement in target design - intended for higher

intensity proton beams - was water cooled and in some assemblies the 3mm

diameter iridium core material was plated to a diameter of 6 mm with

nickel to improve the containment of the fragments. A target of this design

is shown below. Its lifetime was in excess of 107

beam pulses with no significant depletion of effective density.

Schematic sectional drawing and component

parts of the Antiproton Collector (ACOL) target.

This technical note was originally

written in manuscript form, dated 10/10/85.

cdj@mail.cern.ch